Fine Sand Recycling Machine

砂回收機(jī).jpg)

Fine Sand Recycling Machine - Fine Sand Recycling Machine

Product info:

This machine is mainly suitable for large diameter pile foundations in the modern basic projects which are using slurry strengthened wall and circulation drilling processes, trenchless construction and impervious wall projects( such as sand-making sludge, piling sludge, mine tailings sludge). By the fully purification to the sludge, it could well control the sludge property, and reduce the drill-jamming accidents, and improve pore forming quality.

Principle:

The machine is composed of motor, wear-resisting pump, mortar concentrator, linear vibration screen rinse tank and return container. The sludge and water mixed suspension flow into the rinse tank, and then be delivered into concentrator by wear-resisting pump, the sands are separated from the sewage and be sent to the linear vibration screen for dewatering, after that, the sands are sent to the conveyor, and the separated sewage flows back to return tank, then shunts rinse tank.

The features and the advantages:

1. This machine could effectively reduce the loss amounts of the fine sands, which would be controlled within 5-10%. It well solves the problems of finished sands with high fineness modulus and low mountain flour content which happen in the manual material processing system.

2. The linear vibration screen, sieve plate and sprayer are made of new developed synthetic plastics, which have the high wear-resisting lifetime as 5 -6 times as steel, and would not be easily blocked holes.

3. The maximum recycling rate of fine sands from the suspensions could reach to 90%, which is much more superior in technical performance and economical efficiency than other machines.

4. The fine sands could be recycled effectively, which could decrease the workload of the settling pond, and reduce the pond cleaning cost.

5. The machine could short the sands stacking time. The sands from the machine could be transported directly to the market.

6. The machine could be revised or designed as per customers’ requirements to be more suitable for more areas.

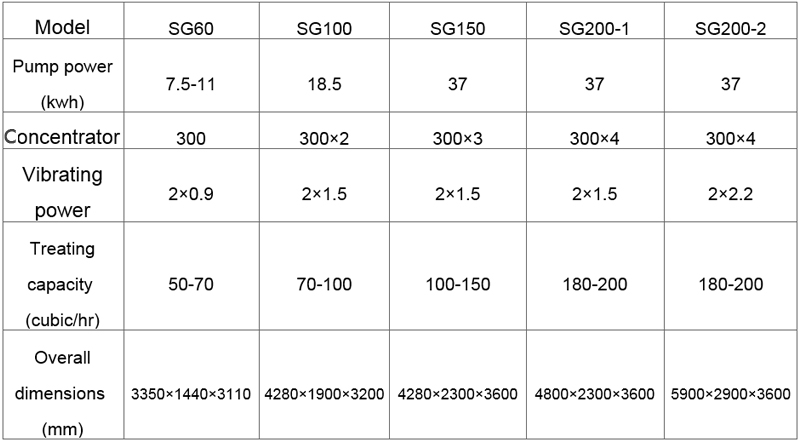

Main technical parameters: